I am interested in your services

We are always looking for new challenges and opportunities to help our clients succeed. If you're searching for a reliable and innovative engineering partner, let’s get in touch.

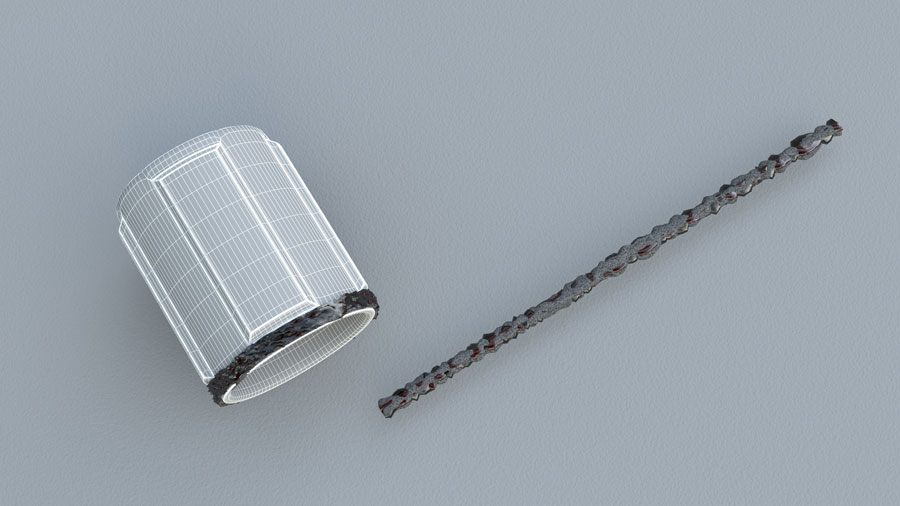

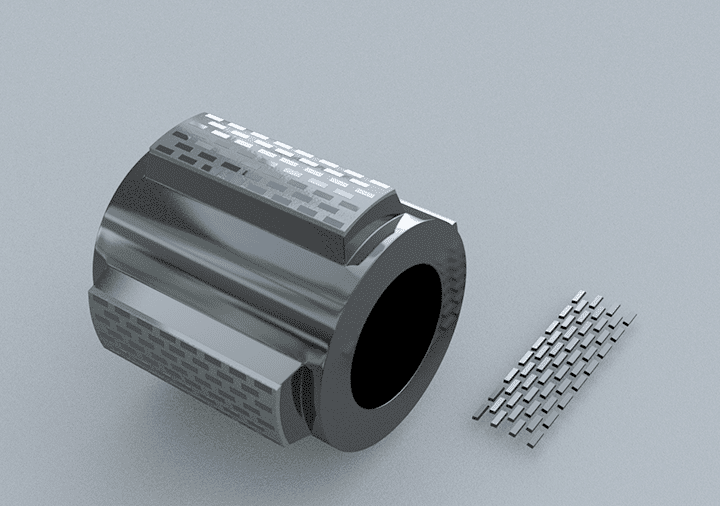

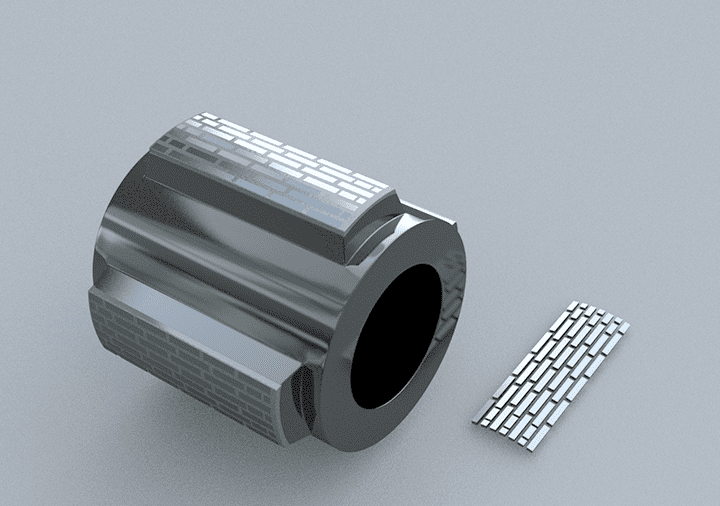

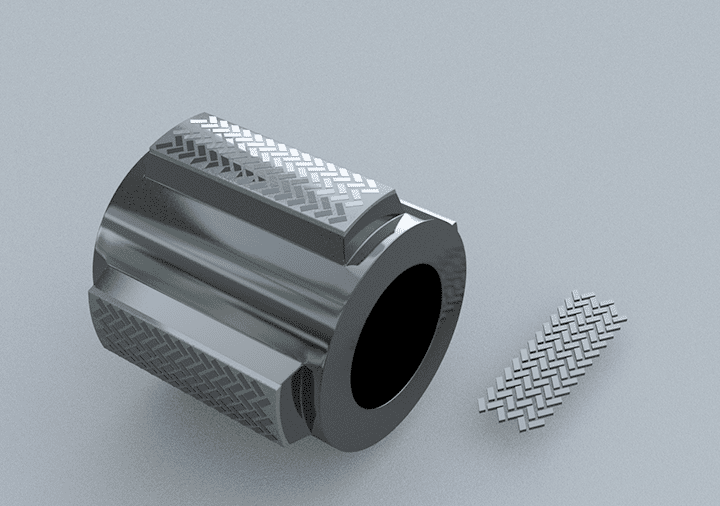

Contact usLION provides specialist hard surfacing processes for reducing wear and erosion on dynamic equipment used in many industries, especially for drilling, mining, and construction.

Using proprietary techniques and processes developed over many years, LION can provide some of the most resilient and proven quality hard surface treatments in the industry, ensuring the provision of the best wear-resistant coatings for all types of downhole tools. The hard surfacing available includes stellite coating, tungsten carbide inserts, tungsten powder and diamond products.